A-PK Machines

The A-PK series machines is a result of collaboration between the Azimut-PK team and engineers from the Shandong Heavy Industries manufacturing plant. Together with the manufacturer, we applied our expert experience and created a line of equipment that meets the technological and economic needs of our customers.

The equipment combines functionality and ease of use, is made from components from world-renowned manufacturers and has an extensive range of options.

A-PK Machine Tools have been jointly produced by Azimut-PK and Shandong Heavy Industries.

These machines deliver optimal functionality paired with user-friendly operation. They are made from best quality components from global manufacturers and have customizable options for diverse production needs.

The price includes VAT, delivery, Installation & commissioning. 1-year warranty.

These machines deliver optimal functionality paired with user-friendly operation. They are made from best quality components from global manufacturers and have customizable options for diverse production needs.

The price includes VAT, delivery, Installation & commissioning. 1-year warranty.

We create. Technologically. Responsibly

We shape the future of engineering together with our customers through expertise, technology, and a commitment to society

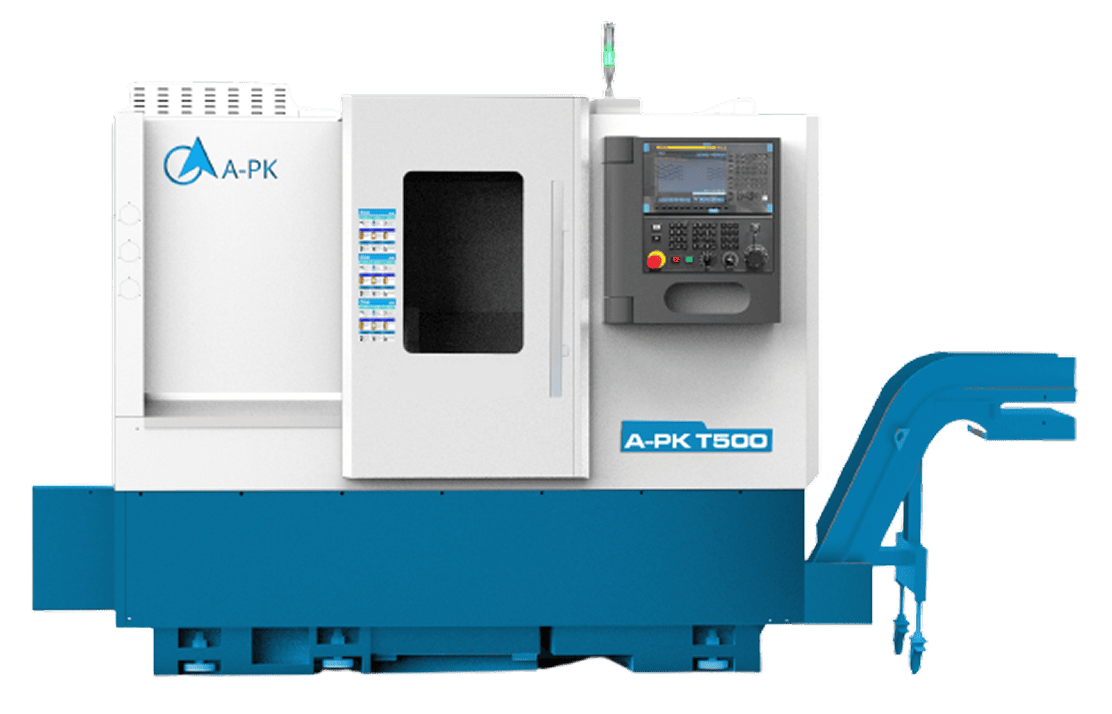

А-РК Т500

Technical specifications

- Max. workpiece diameter: 560 mm (22")

- Max. machining length: 500 mm (19.7")

- Chuck type: 10" hollow hydraulic

- Spindle taper: A2-6

- Spindle motor power: 11/15 kW (14.7/20 HP)

- Spindle through-hole: 66 mm (2.6")

- Bar capacity: 52 mm (2.05")

- Spindle speed: 3,000 RPM

- X/Z axis travel: 230/530 mm (9.1/20.9")

- Tool stations: 12 positions

- Tool size: 25×25/40 mm

- Machine weight: 3,300 kg (7,275 lbs)

Standard configuration

- 30° slanted bed

- Fanuc 0i-TF (3) with Russian language

- Manual Guide function

- Chip conveyor with a cart

- Manual tailstock with hydraulic quill

- TCSM turret (Taiwan)

- Renishaw HPMA tool measurement system

- Tool blocks 2 for facing tools + 2 for axial tools

- Mechanical & software door interlock

- Air conditioner for an electrical cabinet

Additional options

- Siemens 828D (Russian language) with ShopTurn (+ ShopMill for driven tools)

- Fanuc 0i-TF (1) (Russian language) with Manual Guide

- 8" hollow hydraulic chuck

- High-pressure coolant (20 bar) through the turret

- Oil mist collector

- Oil separator

- IEMCA A66 (1.5m) bar feeder with guide rails

- Parts catcher with conveyor and tray

- Robot interface + automatic hydraulic door

- Power turret (BMT55)

- Y-axis

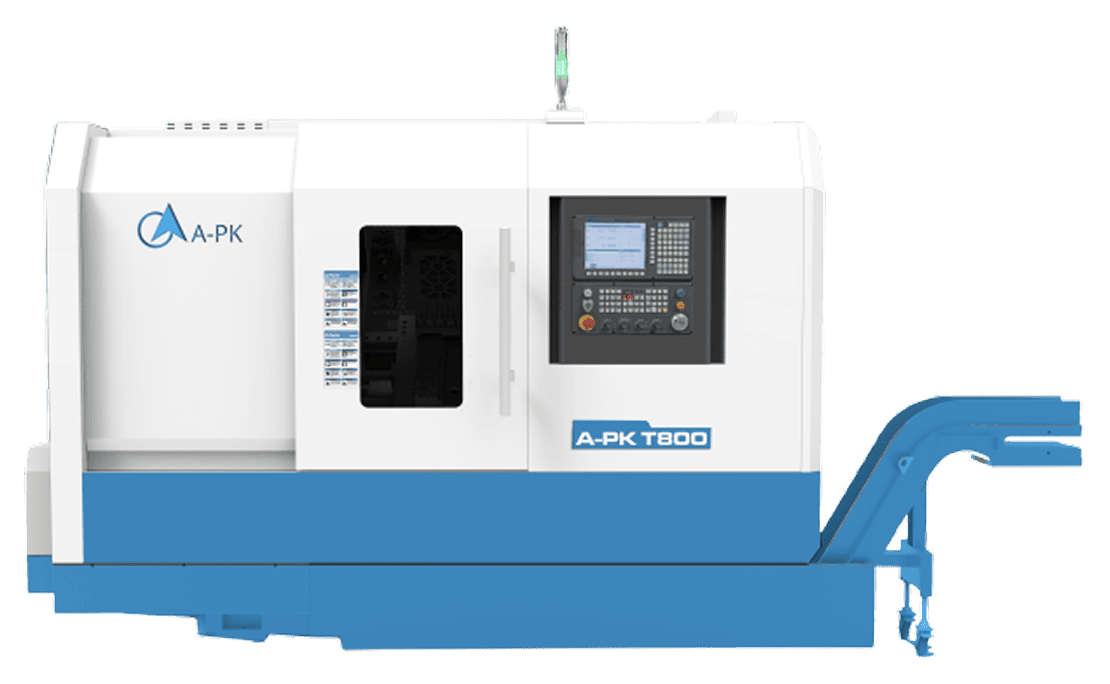

А-РК Т800

Technical specifications

- Max. workpiece diameter: 560 mm (22")

- Max. machining length: 800 mm (31.5")

- Bar capacity: 75 mm (3")

- Chuck: 10" hollow hydraulic

- Spindle taper: A2-8

- Spindle power: 15/18.5 kW (20/25 HP)

- Spindle through-hole: 86 mm (3.4")

- Spindle speed: 3,000 RPM

- X/Z-axis travel: 235 mm (9.25") / 830 mm (32.7")

- Tool stations: 12 positions

- Tool size: 25×25/40 mm

- Machine weight: 4,000 kg (8,820 lbs)

Standard configuration

- 45° slant bed

- Fanuc 0i-TF (3) CNC with Russian language

- Manual Guide function

- Chip conveyor with a cart

- Hydraulic tailstock

- TCSM turret (Taiwan)

- Renishaw HPMA tool measurement system

- Tool blocks 2 for facing tools + 2 for axial tools

- Mechanical & software door interlock

- Air conditioner for an electrical cabinet

Additional options

- 12" hollow hydraulic chuck

- Siemens 828D CNC (Russian language) with ShopTurn (+ ShopMill for driven tools)

- Fanuc 0i-TF (1) CNC (Russian language) with Manual Guide

- 20 bar coolant through turret

- Oil mist collector

- Oil separator

- IEMCA A66 (1.5 m) bar feeder with guide rails

- Parts catcher with conveyor and tray

- Robot interface + automatic hydraulic door

- Power turret (BMT55)

- Y-axis

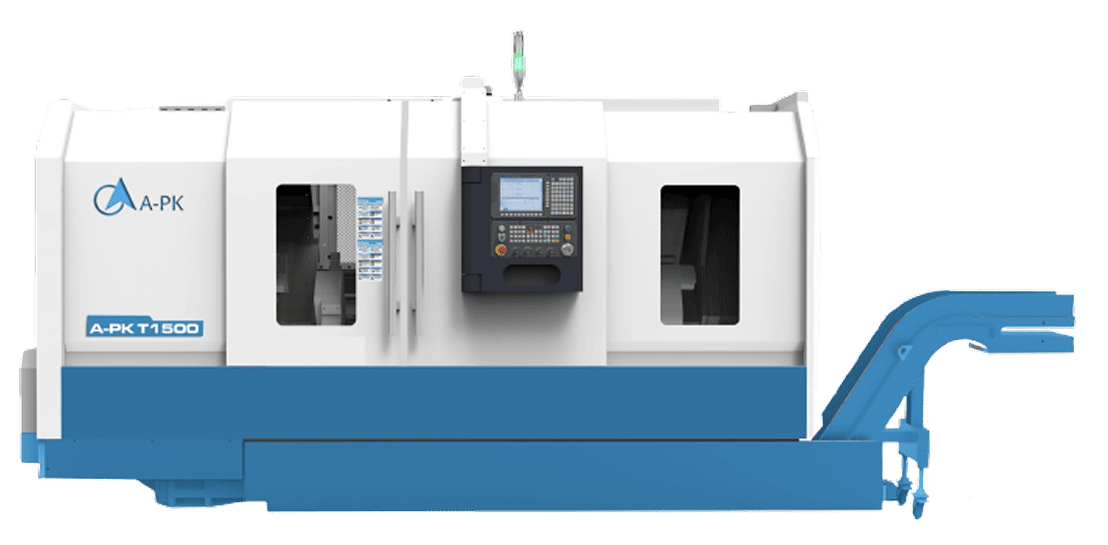

А-РК Т1500

Technical specifications:

- Max. workpiece diameter: 560 mm (22")

- Max. machining length: 800 mm (31.5")

- Bar capacity: 75 mm (3")

- Chuck: 10" hollow hydraulic

- Spindle taper: A2-8

- Spindle power: 15/18.5 kW (20/25 HP)

- Spindle through-hole: 86 mm (3.4")

- Spindle speed: 3,000 RPM

- X-axis travel: 235 mm (9.25")

- Z-axis travel: 830 mm (32.7")

- Tool stations: 12 positions

- Tool size: 25×25/40 mm

- Machine weight: 4,000 kg (8,820 lbs)

Standard configuration:

- 45° slant bed

- Fanuc 0i-TF (3) CNC with Russian language

- Manual Guide function

- Chip conveyor with a cart

- Hydraulic automatic programmable tailstock

- TCSM turret (Taiwan)

- Renishaw HPMA tool measurement system

- Tool blocks 2 for facing tools + 2 for axial tools

- Mechanical & software door interlock

- Air conditioner for an electrical cabinet

Additional option:

- 12" hollow hydraulic chuck

- Siemens 828D CNC (Russian language) with ShopTurn

- Fanuc 0i-TF (1) CNC (Russian language) with Manual Guide

- 20 bar coolant through turret

- Oil mist collector

- Oil separator

- IEMCA A66 (1.5 m) bar feeder with guide rails

- Parts catcher with conveyor and tray

- Robot interface + automatic hydraulic door

- Power turret (BMT55)

- Y-axis

А-РК V800

Technical specifications:

- Table size - 1000 × 550 mm

- Maximum table load - 500 kg

- Spindle motor power - 11/15 kW

- Spindle speed - 8000 rpm

- Spindle taper - BT40

- Spindle drive type - Belt-driven

- X/Y/Z axis travel - 800 × 550 × 500 mm

- X/Y/Z rapid traverse rate - 24/24/20 m/min

- X/Y/Z positioning accuracy - 0.005/0.005/0.005 mm

- Tool magazine capacity - 24 tools

- Machine weight - 5700 kg

Standard configuration:

- Fanuc 0i-MF (3) CNC with Russian language and Manual Guide

- Spindle oil cooling

- Chip conveyor with a cart

- Renishaw TSR27 tool measurement system

- Mechanical & software door interlock

- Air conditioner for an electrical cabinet

Additional options:

- Siemens 828D CNC (Russian language) with ShopMill

- Fanuc 0i-MF (1) CNC (Russian language) with Manual Guide

- 12,000 RPM direct drive spindle

- 18,000 RPM motor-spindle

- BT50 spindle taper

- Coolant-through-spindle supply (20, 30, 40 bar)

- Oil mist collector

- Oil separator

- 40-tool magazine

- 4th axis rotary table (255 mm)

- Tilting-rotary hydraulic table (3+2 axis, 255 mm)

- Column height extension (+200 mm)

- Robot interface + automatic hydraulic door

- Renishaw OMP60 workpiece measurement system

- Tooling package for BT40/BT50

А-РК V1100

Technical specifications:

- Table size - 1200 × 600 mm

- Max. table load - 1000 kg

- Spindle motor power - 11/15 kW

- Spindle speed - 8000 rpm

- Spindle taper - BT40

- Spindle drive type - Belt-driven

- X/Y/Z axis travel - 1100 × 600 × 600 mm

- X/Y/Z rapid traverse rate - 24/24/20 m/min

- X/Y/Z positioning accuracy - 0.006/0.006/0.006 mm

- Tool capacity - 24 tools

- Machine weight - 6500 kg

Standard configuration:

- Fanuc 0i-MF (3) with Russian language and Manual Guide

- Spindle oil cooling

- Chip conveyor with a cart

- Renishaw TSR27 tool measurement system

- Mechanical & software door interlock

- Air conditioner for an electrical cabinet

Additional options:

- Siemens 828D (Russian language) with ShopMill

- Fanuc 0i-MF (1) (Russian language) with Manual Guide

- 12,000 RPM direct drive spindle

- 18,000 RPM motor-spindle

- BT50 spindle taper

- Coolant-through-spindle (20, 30, 40 bar)

- Oil mist collector

- Oil separator

- 40-tool magazine

- Robot interface + automatic hydraulic door

- Renishaw OMP60 workpiece measurement system

- Tooling package for BT40/BT50

- 4th axis rotary table (255 mm)

- 4th axis rotary table (320 mm)

- 2-axis tilting-rotary hydraulic table (255 mm)

- 2-axis tilting-rotary hydraulic table (320 mm)

- Column height extension (+200 mm)

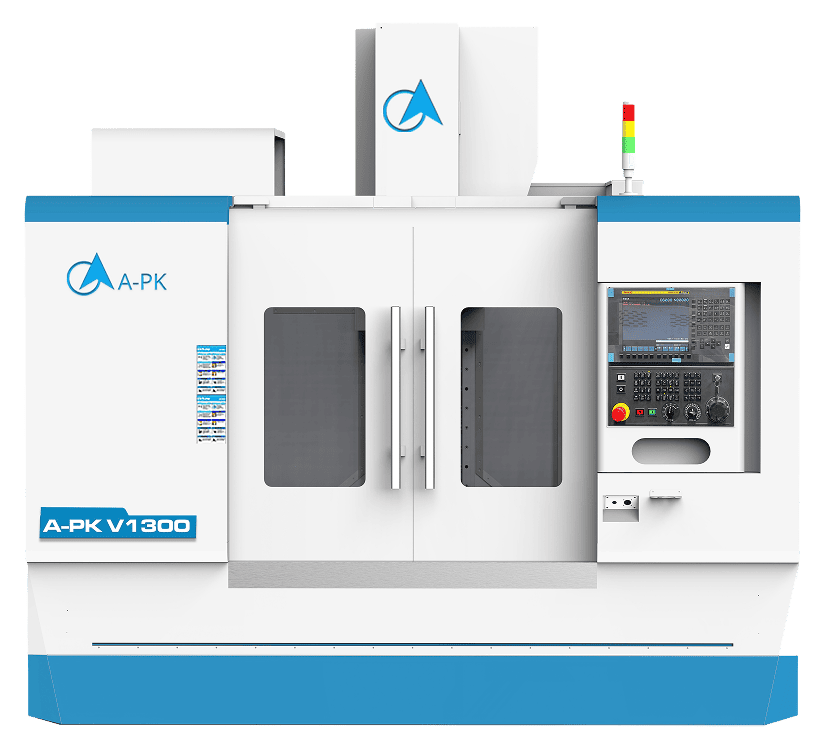

А-РК V1300

Technical specifications:

- Table size - 1500 × 700 mm

- Maximum table load - 1000 kg

- Spindle motor power - 15/18.5 kW

- Spindle speed - 6000 rpm

- Spindle taper - BT50

- Spindle drive type - Belt-driven

- X/Y/Z axis travel - 1300 × 700 × 650 mm

- X/Y/Z rapid traverse rate - 24/24/18 m/min

- X/Y/Z positioning accuracy - 0.006/0.006/0.006 mm

- Tool magazine capacity - 24 tools

- Machine weight - 12800 kg

Standard configuration:

- Fanuc 0i-MF (3) CNC (Russian language)

- Manual Guide function

- Spindle oil cooling

- Chip conveyor with a cart

- Renishaw TSR27 tool measurement system

- Mechanical & software door interlock

- Air conditioner for an electrical cabinet

Additional options:

- Siemens 828D with Russian interface (includes ShopMill software)

- Fanuc 0i-MF (1) with Russian interface (includes Manual Guide)

- 8,000 RPM direct drive spindle

- 12,000 RPM direct drive spindle (BT40)

- 18,000 RPM motor-spindle (BT40)

- BT40 spindle taper

- Coolant-through-spindle (20, 30, 40 bar)

- Oil mist collector

- Oil separator

- 40-tool magazine

- 4th axis rotary table (255 mm)

- 4th axis rotary table (320 mm)

- 2-axis tilting-rotary hydraulic table (255 mm)

- 2-axis tilting-rotary hydraulic table (320 mm)

- Column height extension (+200 mm)

- Robot interface + automatic hydraulic door

- Renishaw OMP60 workpiece measurement system

- Complete tooling package for BT40/BT50 tool holders

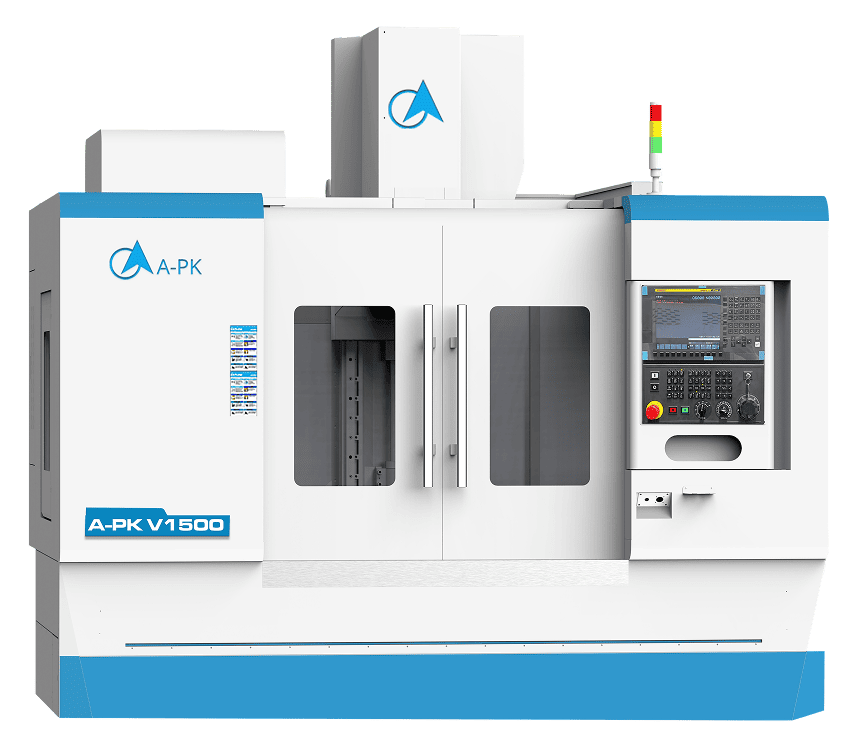

А-РК V1500

Technical specifications:

- Table size- 1800 × 800 mm

- Maximum table load - 1200 kg

- Spindle motor power - 15/18.5 kW

- Spindle speed - 6000 rpm

- Spindle taper - BT50

- Spindle drive type - belt-driven

- X/Y/Z axis travel - 1500 × 800 × 700 mm

- X/Y/Z rapid traverse rate - 24/24/15 m/min

- X/Y/Z positioning accuracy - 0.012/0.01/0.01 mm

- Number of tools - 24 pcs

- Weight - 13500 kg

Standard configuration:

- CNC Fanuc 0i-MF (3) (Russian interface and Manual Guide

- Spindle oil cooling

- Chip conveyor with a cart

- Renishaw TSR27 tool measurement system

- Mechanical and software door interlock

- Air conditioner for an electrical cabinet

Additional options:

- CNC Siemens 828D (Russian language) with ShopMill

- CNC Fanuc 0i-MF (1) (Russian language) with Manual Guide

- 8000 RPM direct drive spindle

- 12000 RPM direct drive spindle (BT40)

- 18000 RPM motor-spindle (BT40)

- BT40 spindle taper

- Coolant-through-spindle (20, 30, 40 bar)

- Oil mist collector

- Oil separator

- 40-tool magazine

- 4th axis rotary table (255 mm)

- 4th axis rotary table (320 mm)

- 4th axis rotary table (400 mm)

- 2-axis tilting-rotary hydraulic table (255 mm)

- 2-axis tilting-rotary hydraulic table (320 mm)

- 2-axis tilting-rotary hydraulic table (400 mm)

- Column height extension (+200 mm)

- Robot interface + automatic hydraulic door

- Renishaw OMP60 workpiece measurement system

- Tooling package for BT40/BT50

Laser complexes for quenching and surfacing "Termolazer"

Band saw Machines

Laser cutting Machines

CNC milling machines

CNC turning machines

Technology

Equipment selection

Engineering support

Installation & commissioning

Metalworking to order

Our Journey: 8 Years of Pioneering Excellence

In 2026, Azimut-PK celebrates its 9th anniversary – not just as a timeline, but as a transformative journey from a metalworking equipment supplier to a trusted technology partner for Russia’s engineering enterprises.

Defying the statistics showing only 1% of Russian companies survive beyond 5 years*, we’ve built a loyal client base and sustained growth despite market challenges. This kind of resilience makes us a reliable partner.

The advantage of Azimut-PK lies in its team industrial expertise. The company’s founder brings 9 years of machine tool sales experience with DMG MORI and Yamazaki Mazak, serving regions from Perm Krai to the Volga Federal District. Our technical partner has evolved from a machine operator to owning a full-cycle mechanical production facility.

The synergy of commercial acumen and engineering rigor guarantees technologically sound and cost-efficient solutions.

According to 2024 FinExpertiza research (using official data of Federal Tax Service)

Key milestones of our journey

2017

2020

2023

2024

2025

The foundation of Azimut-PK

3-Year benchmark, focus on the delivery of CNC turning & milling machines

Direct manufacturer partnerships. We secured first-tier supplier status with manufacturing factories

The registration of "А-РК" trademark for the production of CNC machines under our own brand

The expansion of the range of supplied equipment with 7 machines by A-PK

Why customers trust us

Innovation

Cutting-edge technology

Technology proving ground. Our own production facility tests all solutions

Support

Uninterrupted production and technological support

7 days technical hotline

Cost Efficiency

Supply of machines

from the manufacturer without intermediaries

Direct contracts with manufacturers

Custom-tailored solutions

8-year specialization in metal-cutting machinery

Risk-free operations

Vetted supplier network

Expertise

Reliability

Benefits for clients

Proof

Why customers trust us

Innovation

Cutting-Edge Technology

Technology proving ground. Our own production facility tests all solutions

Support

Uninterrupted production and 24/7 operational support

7 days technical hotline

Cost Efficiency

Supply of machines

from the manufacturer without intermediaries

Direct contracts with manufacturers

Custom-Tailored Solutions

8-year specialization in metal-cutting machinery

Risk-Free Operations

Vetted supplier network

Expertise

Reliability

Benefits for clients

Proof

Feedback

Chaykovsky zavod Mechanika LLC

(Chaykovsky, Perm Krai, Russia)

On behalf of Mechanka JSC, we express our appreciation for your exceptional service: timely delivery of a CNC tube bending machine, comprehensive operator training, and ongoing technical support during commissioning.

This equipment has enabled us to resolve critical production challenges and reduce labor intensity in tubular structure manufacturing by 40%.

We recommend expanding standard tooling options for diverse pipe configurations to further enhance value.

We look forward to future equipment procurements and continued partnership.

This equipment has enabled us to resolve critical production challenges and reduce labor intensity in tubular structure manufacturing by 40%.

We recommend expanding standard tooling options for diverse pipe configurations to further enhance value.

We look forward to future equipment procurements and continued partnership.

A. Bevzenko

General Director

Yargazarmatura LLC

(Chaykovsky, Perm Krai, Russia)

We sincerely appreciate our productive collaboration in 2022. The CNC milling machine you supplied was delivered on schedule and commissioned without any issues, meeting all our operational requirements.

We value this partnership and look forward to continuing our successful cooperation in the future.

We value this partnership and look forward to continuing our successful cooperation in the future.

S. Dudarev

General Director

Profi LLC

(Perm, Perm Krai, Russia)

Profi LLC expresses its appreciation for the cooperation and thanks the staff of Azimut-PK LLC for their high-quality work and the successfully commissioned automatic band saw with CNC in 2020. The experience of cooperation allows us to speak about Azimut-PK as a reliable partner who clearly fulfils his obligations. We really appreciate the attentive and responsible attitude, efficiency, professionalism of the staff and individual approach.

D. Shumilov

General Director

Neotech LLC

(Perm, Perm Krai, Russia)

In 2019, Azimut-PK successfully delivered and commissioned a semi-automatic band saw machine at our facility. The equipment has demonstrated consistent reliability and meets all specified performance characteristics without any quality concerns.

V. Khromtsov

Chief Executive Officer

Our location

Perm, Perm Krai, Russia

Perm, Perm Krai, Russia

Ways to reach us:

Сontacts